The BALLAST WATER MANAGEMENT-BWM Convention entered into

force on 8 September 2017.

Introduction BWTS

Presently the

IMO urged the ship’s owner’s to concerning about the ballast water treatment

system to avoid the marine biological Pollution caused by the conventional

ballast water exchange system IMO-D1.

Hence the IMO came up with the new regulation to mitigate

such violation is the ballast water treatment IMO-D2 system.

Here you can get the generic working details of ballast

water treatment system (BWTS) or ballast water management system (BWMS) for

your better knowledge of the operation.

IMO-D1: Ballast water exchange method

IMO-D2: Ballast Water Treatment method

IMO-D3: Approval requirements for Ballast Water Management

systems

IMO-D4: Prototype Ballast Water Treatment Technologies

IMO-D5: Review of Standards by the Organization

About BWTS-Ballast Water Treatment System

Total four

types of ballast water treatment system available as of now in the market and

here we will discuss the most commonly used electrolysis and UV Ballast

Water Treatment Method.

- Electrolysis method

- UV treatment method

- Magnetic separation method

- Gas Treatment method

Electrolysis method

The electrolytic method is to add or dosing the chloride/chlorine water in the ballast tank to kill the marine organism.

The electrolysis method is classified by two types

a. Side stream

method

b. Full Stream

method

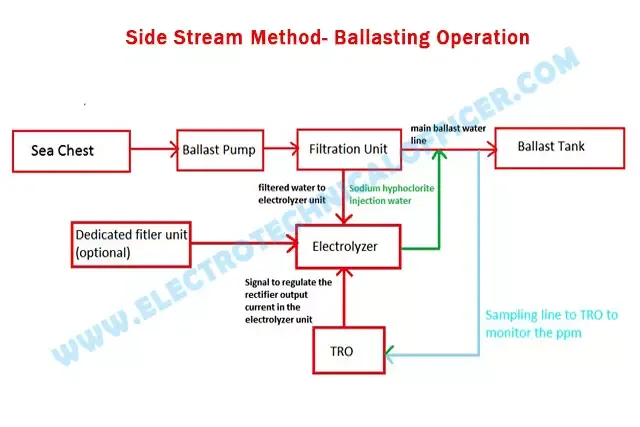

a. Side stream method

Summary of side stream method:

It consists of the following major unit to achieve the

treated ballast water for the ship’s

- Filtration unit

- Electrolyser unit

- Neutralizer unit

- TRO (Total Residual Oxidant) monitoring unit

Filtration-side stream method

Filtration is

the pre-treatment of the BWTS and the main role of this system is to filter

the marine organism, sediments, and large plankton, a marine organism. It is

equipped with the auto backwashing assembly to pump out the filtered particles

from the filtration unit without interrupting the ballast operation and the

backwash takes place automatically when differential pressure reaches the set

point or the timer set value for the backwashing operation.

The filter

size is about 50-micron candle type and it has the pressure sensor to monitor

the pressure continuously in the filter chamber and followed by some control equipment’s

such as a timer, relay, flow transmitter.

After completion of ballasting de-ballasting operation the

filter unit used to be filled with fresh water in order to protect the filter

corrosion.

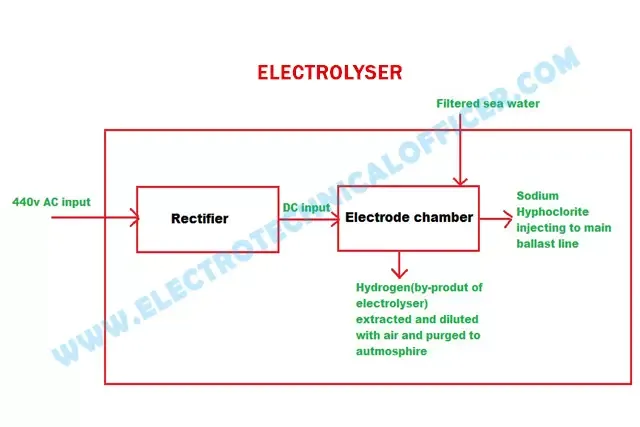

Electrolyser-side stream method

The filtered

water from the main filter unit is fed to the electrolyzer unit or the

dedicated filtration unit (optional) is fitted for the electrolyzer to produce

the oxidant which is Sodium Hypochlorite (disinfectant) NaOCl.

Hydrogen is the by-product of the electrolyser and it’s

extracted from the unit and diluted with air by the help of by gas separator

and electric blower and purged into the safe atmospheric zone.

The generated

Sodium hypochlorite is injected to the main ballast line and it’s reacted in the

pipe with organic and inorganic species such as larva, spores, pathogens, etc.,

The

sampling line from the main ballast line to TRO unit to monitor the oxidant

value which should be in the range of 6.5ppm-9ppm during ballasting extracted

diluted.

Electrolyser operation only during the ballasting operation

NOTE

The

electrolyzer feedwater must be heated up through the heat exchanger if the

actual temperature of the seawater falls below 15oC to avoid the

rectifier high current trips and if the ship enters the freshwater port ship

should be filled up with the saltwater in the dedicated saltwater tank or aft

peak tank prior to entering into the freshwater region, because the saltwater

is most needed for producing the disinfectant.

Neutralizer-side stream method

Neutralizer unit is used

to neutralizing the residual oxidant (chlorite) in the treated ballast water

which can’t discharge overboard directly without neutralized. That the

remaining oxidant might have harmful for the marine organism in the ballast

tank.

Na2s2o3sodium

thiosulfate is the neutralizing agent this powder agent mixed

with water and stored in the form of a solution in the neutralizer tank and kept

ready for injection during de-ballasting, this is called neutralization or

de-chlorination.

Total Residual Oxidant (TRO)-side stream method

The

TRO unit has the two types of chemical solutions in the TRO cabinet to carry out

the chemical calculation of the treated water. Buffer solution and total

chlorine indicators are the two types of chemicals.

Ballasting-side stream method

TRO is used to analyze or

determine the total residual oxidant concentration in the mainline during

ballasting and this monitoring is carried out throughout the ballasting

operation simultaneously transmits the signals to the PLC or control unit.

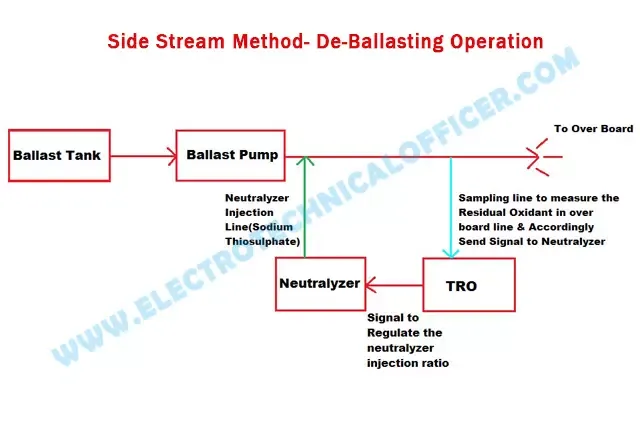

De-ballasting-side stream method

Prior discharge/ de-ballasting the treated water should be

neutralized. During de-ballasting, the

sampling pump sucks the tiny amount of treated water from the de-ballasting

line to TRO analyzer for analyze and determine the residual oxidant value and

send the signal to the control unit. According to the received signal, the from the control unit (PLC) the neutralizer will control the injection ratio of sodium

thiosulfate solution to obtain the target value which is 0.1ppm before it’s

discharged.

Miscellaneous parts

Except for this above mentioned major part

in the BWTS few more parts or sensors are employed in the BWTS operation

- Rectifier used to convert the AC into DC for the electrodes in the electrolyzer

- Control cabinet or PLC panel to carry out the operation with embedded program

- Flow transmitter for various liquid flow measuring and transmitting to the PLC

- Electrolytic injection pump during ballasting operation

- Neutralizer injection pump during de-ballasting operation

- Neutralizing tank to store the sodium thiosulphate solution

- Hydrogen separator with an electric blower to separate the gas from and diluted

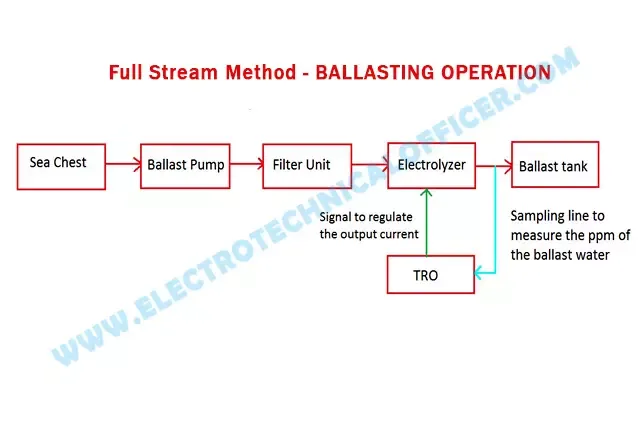

b. Full Stream Method-BWTS

The full stream operation is almost

same as side stream with small changes like the electrolyzer unit installed

consecutively in the main ballast line instead of away in the line like side

stream.

De-ballasting operation is the same as the side stream

UV TREATMENT

Ultra

Violet disinfection method consists of the following major processor parts to achieve

the treated ballast water

1. Filter Unit

2. UV unit

3. Monitoring and Control

panel

Filter Unit-UV Treatment Method

The filter unit is installed in the discharge side of the

ballast water pump and it’s fully automatic in terms of cleaning or back-washing

the filter unit without affecting the filtration process. During ballasting, the

large marine micro and macro organism, larva, sediments are filtered and flushed

overboard by the auto cleaning process. This pre-treated filtration unit is sophisticated

and easy to operate and it has the 50-micron filter and self-cleaning assembly

which is the auto cleaning unit.

Two pressure sensors are

installed to measure the inlet and outlet pressure of the filter chamber and

installed with the limit switch, flow transmitter, pressure gauges.

Drain

valve in the filter chamber is used to drain the filter unit in case of any

maintenance in the chamber. After the completion of the ballasting operation

it’s recommended to fill the chamber with the freshwater in order to prevent

the corrosion of the filter and the inside filer chamber due to the prolonged

storage of the seawater.

UV Unit-UV Treatment Method

The Ultra Violet system uses the high-intensity UV light to

destroy the marine living organism present in the seawater after the main

filter unit such as larva, bacteria, viruses, and yeasts. It has the medium

pressure UV lamp the Ultraviolet lamp fitted perpendicular to the flow of

water for efficient disinfection. UV unit has the stainless steel chamber and

the UV emitting arc tubes fitted in it the UV arc tubes are fitted with a

quartz sleeve and mounted with the chamber the quartz should have the high purity

for the maximum UV transmission and followed by the electrically

operated(motor) mechanical auto wiper for quartz cleaning purposes.

The seawater passes through this stainless-steel

chamber via the high-intensity ultraviolet rays and the UV intensity sensor

monitor the actual intensity and transmit the signal to the control unit also this the system is programmed with the ‘low UV intensity’ alarm when the UV intensity

falls below the set point. A temperature sensor will shut down the system in

condition of low or no water flow to avoid the overheating of the UV lamp.

In the UV disinfectant process the

ultraviolet rays are emitted in the titanium dioxide plate to generate the

radical to kill or sterilize the marine aquatic organism and the fungi. An atom

or a molecule with an unpaired electron is known as the radicals by the

radiating light of specific wavelength titanium dioxide generate the act

oxygen and hydroxyl (OH), in some of the UV systems the UV rays are used to

treat the water and the marine organism can be regenerated in the ballast water

tank hence it should be retreated before discharging to the sea to treat the

marine organism.

MONITORING and CONTROL UNIT-UV Treatment Method

The monitoring and control unit has the full charge of the

ballasting de-ballasting operation of the system and it is embedded with the

PLC program with a touch screen for auto operation monitoring of the various

operation of the equipment employed in the UV BWTS system.

It is performed by real-time monitoring while

storing the data by the various sensor, electric ballast for the UV lamp is

controlled by this unit and other associated equipment.

The control system based on the programmable logic control system is activated and de-activates the ultra

violet lamp via ballast to maintain the sufficient UV dose.

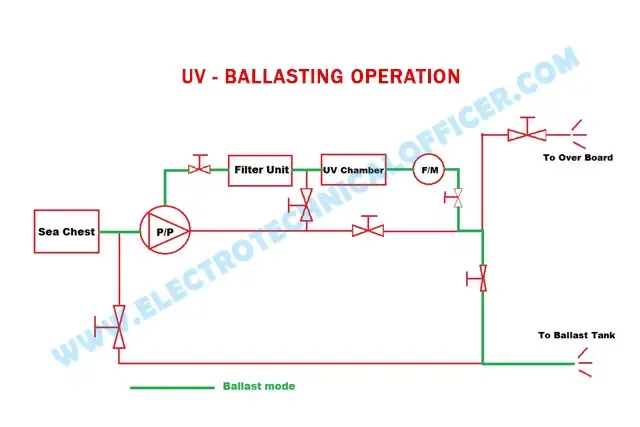

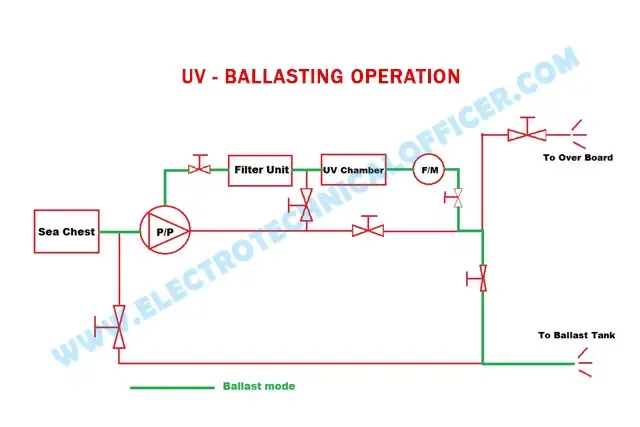

OPERATION-UV Treatment Method

A. Warning up mode

B. Ballasting mode

C. De-ballasting mode

D. Bypass mode

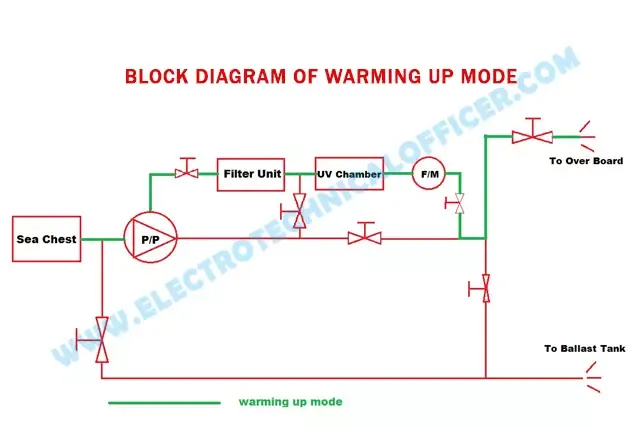

A. Warming Up Mode-UV Treatment Method

UV lamp

requires sufficient time to reach the full power which is approx. 5 min so it

is necessary to start up the warm-up mode before the ballasting or de-ballasting mode for the better performance by the system.

In this case, water pumped

from the sea chest and passes through the filter unit and UV chamber the

treated water discharged to sea through the overboard valve instead of the

ballast tank until the operator changed the ballasting mode.

Water Flow: sea chest Ballast pump ---> Filter Unit ---> UV Chamber ---> Flow Meter ---> O/B

B. Ballasting Mode-UV Treatment Method

During

ballasting operation water pumped from the sea chest and passed through the

main filter unit for the pre-treatment to filter the large planktons, larva,

sediments and other marines micro-macro organism by the 50-micron candle type

filter.

It is equipped with the auto back

washing assembly to pump out the filtered particles from the filtration unit

without interrupting the ballast operation and the backwash takes place

automatically when differential pressure reaches the set point or the timer set

value for the back-washing operation.In the UV chamber, the primary treatment process takes place by the high-intensity medium pressure ultraviolet and depending

upon the flow rate of the ballast water, the UV lamp ballast is activated and de-activated by the PLC to maintain the sufficient UV dose to kill the marine the organism in the primary treatment. It requires the high voltage power for the

medium pressure lamp inside the UV chamber, this type of UV treated BWTS is

not using any kind of chemicals during ballasting except titanium dioxide-based

UV treatment system which can produce the oxygen and hydroxyl (OH) chemicals

for the disinfection process which have the strong disinfectant.

Water Flow: sea

chest ---> Ballast pump ---> Filter Unit ---> UV Chamber ---> Flow Meter ---> B/T

C. De-Ballasting Mode-UV Treatment Method

During de-ballasting operation the

water sucked from the ballast tank instead of the sea chest and passes through

the UV chamber for the second UV dose during de-ballasting. Because after the

ballasting operation the marine organism can reproduce in the ballast water

tank hence it is very important that the water should retreat before

discharge to the shore Valves are lined

up automatically when the de-ballasting mode operation commenced and the valves

are lined up and operated by the monitoring and control unit (PLC).

Water Flow: Ballast tank ---> Ballast pump ---> UV Chamber ---> Flow Meter ---> O/B

D. By-Pass Mode-UV Treatment Method

In this mode, the system can run

without the treatment cycle in case of any stoppage due to malfunction or any

local regulation’s involved to avoid using the treatment system, all

precautions to be taken while by-passing the ballast water treatment system and

relevant persons to be duly informed.

2 Comments

Thank you sir

ReplyDeleteSir plz tell regulations of BWTS ?

ReplyDeleteWe love to hear your comments on this article, so that we may better serve you in the future.