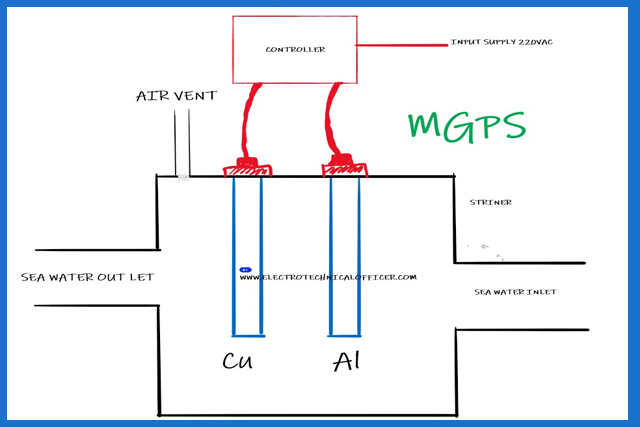

MGPS – Marine Growth Prevention System

The seawater system is protected against fouling by the anti-fouling system.

The system

protects against marine growth and corrosion by passing an electric current

through anodes placed at the seawater intakes.

The marine

growth protection anodes (Cu) are made from copper and the trap corrosion

anodes (Al) are made from aluminium alloy. The anodes are fitted in the suction

strainers.

The port

and starboard side strainers each have two MG anodes and two TC (Trap

corrosion) anodes.

A low

current must be maintained at the sea suction strainer which is not operating.

Working of MGPS

MGPS is based

on the electrolytic principle and consists of copper, and aluminium anodes

Reaction

at copper Anode:

The Cu anodes release copper ions when an electric voltage is applied. These Cu ions combine with oxygen in the water to form cuprous oxides which have a strong toxic effect on marine organisms which enter the system, thereby minimizing their growth and fouling of the seawater system.

|

Anode reaction |

Cu → Cu2 + + 2e-

|

|

Cathodic reaction |

3 H2O + 2e- → H2 + 2OH- |

|

Colloid formation |

Cu2+ + 2OH- → Cu2O |

Reaction

at Aluminium Anode:

The TC

anodes form aluminium hydroxide when an electric current is applied. This forms

an anti-corrosion barrier on the steel pipework of the seawater system.

|

Anode reaction |

Al → Al 3 + 3e-

|

|

Cathodic reaction |

3 H2o + 3e- → 3/2H2 + 3OH- |

|

Colloid formation |

Al3+ + 3OH- → Al(OH)3 |

General

Specifications of MGPS

Power

supply: 220VAC 60 Hz Maximum output 20A DC

Anodes:

Copper (Cu) and Aluminum (Al)

What is the life of MGPS anodes?

Anode life

is approximately 2.5 years.

Effects of low Current settings

Too low a

current results in insufficient protection.

Effects of High current settings

Too high a

current results in rapid wasting of the anodes.

Higher

currents than necessary will result in the rapid depletion of the anodes and

the system will not be protected when the anodes have wasted away.

The rapid

depletion of the copper anodes can result in the deposition of the copper on

the suction strainer causing partial blockage of the strainer. The condition of

the strainers and the anodes should be checked at six-monthly intervals to

ensure that this depletion is not taking place.

When do we have to reduce the Anode current?

If the seawater flow rate is reduced from this value the current applied to the anodes

should also be reduced.

Incorrect the setting of the current can result in inadequate protection against marine

growth and corrosion.

Adjustment

of current should only be made after consulting the Maker or Operating Manual.

What is the operating current of MGPS Anode?

Generally,

|

Anode |

In operation current |

Not operating current |

|

Al Anode |

3.3 A |

0.05 A |

|

Cu Anode |

1.7 A |

0.05 A |

A low current must be maintained at the sea suction strainer which is not operating.

It is

essential that the correct current is always applied to the anodes at the

operating sea water suction chest as the maker advises.

Which of the anodes decomposes faster?

Copper (Cu)

anode.

What is electrolysis?

Electrical

current flow through the liquid causes a chemical reaction.

What is the concentration of copper?

concentrations of copper are extremely small -less than 2

parts per billion

Maintenance

Check the

current readings and note them down every day.

The anodes

must be checked periodically in order to ensure that they are wasting at the

expected rate.

3 Comments

Gain lots about the mgps ,thanks for sharing

ReplyDeletehow to calculate current setting and life of MGPS electrode

ReplyDeleteIf fouling content is more than 10 ppm, how much ampere of power supply must be applied?

ReplyDeleteWe love to hear your comments on this article, so that we may better serve you in the future.